Technical Specifications

1. Hardware:

(1) Laser Probe:

1) Rapid Profile Sensor

○ Low power diode line laser (Class II)

○ Laser technology: Non-contact triangulation line laser

○ Number of scan lines: Min.4 line/sec, Max 32 line/sec or more

○ Line Length: 12mm or more

○ Accuracy: 0.006mm or less

○ 2D CCD (Charge Coupled Device) arrays: Two CCD

(2) Body:

1) Work envelope capacity: 750mm X 1000mm X 600mm or more

2) Work table load capacity: 500kg or more

3) Rotary table: 360° rotation

4) Repeatability: 0.006mm or less

5) 3D Volumetric accuracy: 0.02mm or less

6) Measuring table material: Granite

7) Must be CNC type that automatically sets X, Y, Z - axes. And Z- axis should have Z-Search function for automatic data search.

(3) Scanning Method:

1) Point to Point scan mode: 4 line/sec or more

2) Continuous Scanning mode: 16 line/sec or more

3) Dynamic Scanning mode: 32 line/sec or more

4) Manual Scanning mode

(4) Scan Controller:

1) Pentium 4 / CPU 3GHz or more

2) 4GB RAM or more

3) 160GB Hard Drive or more

4) OS: Windows 7 or XP

5) 19" LCD Monitor

6) 40X CD-RW

2. Scan Software

Scanning and data editing capabilities should be in one software and should use Surveyor Scan Control (SSC) software which can edit scanned data easily and accurately.

1) Automatic search and recognition of X, Y, Z, V, W coordinates and rotation angle

2) Automatic Z-search function for Depth of Field

3) Laser environment setting, and user setting with parameters

4) Automatic repeat scan function using Run file (Programmable)

5) Function to set direction, density, and form during Scanning operation

6) Blend Function: no stop mode in scan

7) 3/2D Intensity Filtering (Sampling)

8) Recognize the scanned data in various angles in Rotary table and make complete 3D Solid Form (Combine into single data sheet)

뿌리장비 예약

장비 상세정보

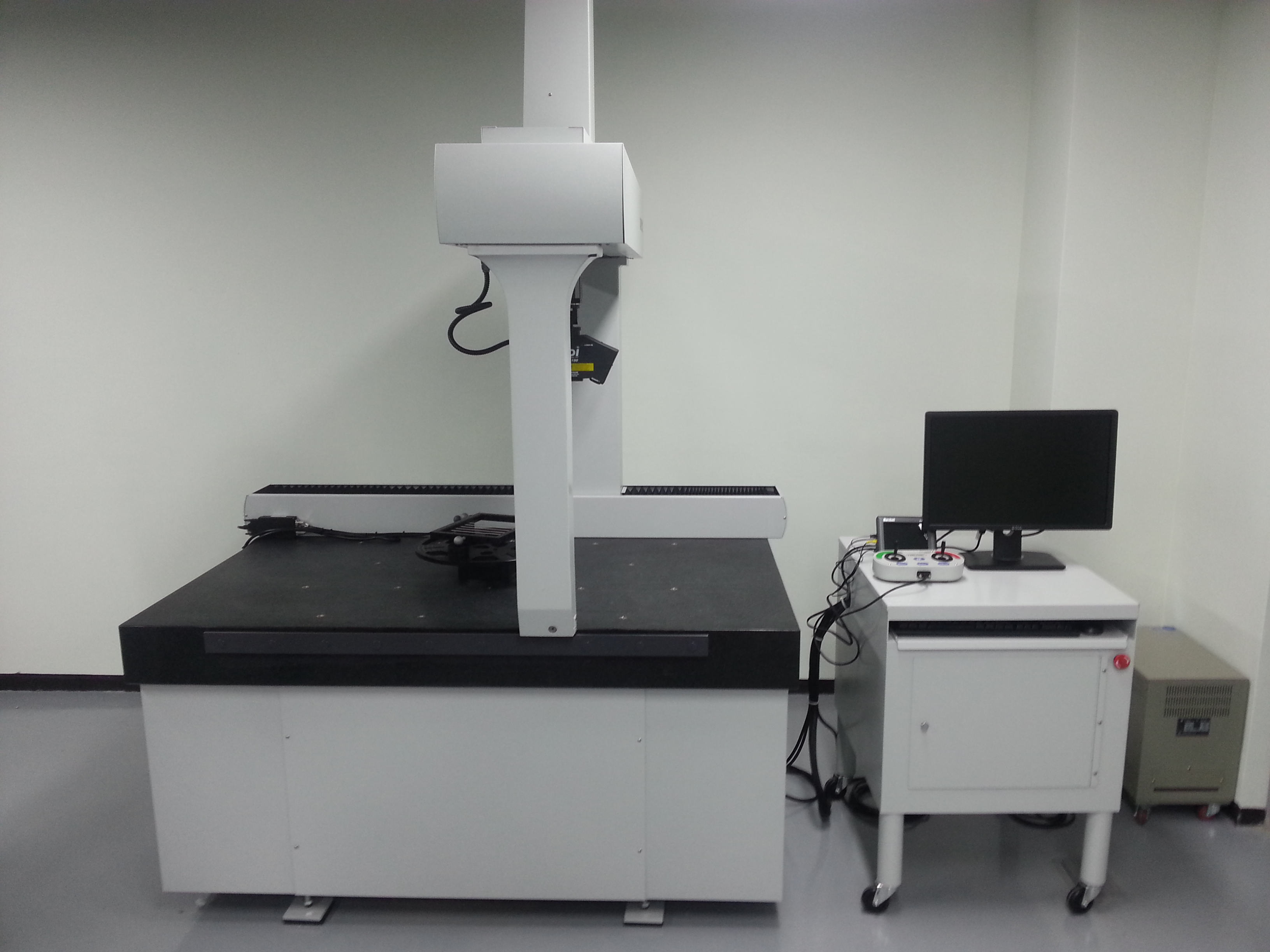

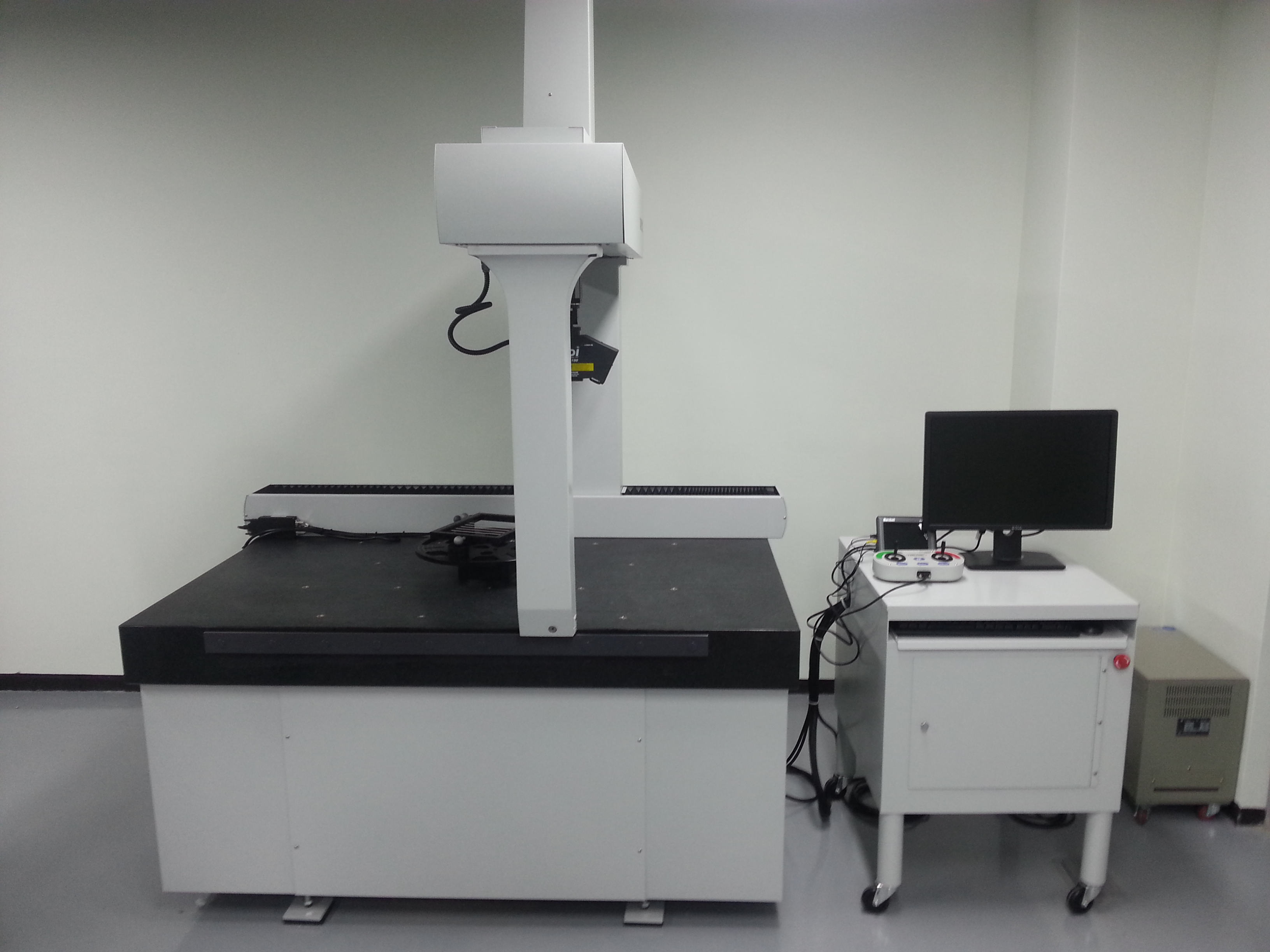

| 장비사진 | 장비명 | 3차원 레이져 스캐닝 시스템(3D laser scanning system) | ||

|---|---|---|---|---|

|

제작사 | LDI | 모델명 | DS-3040 |

| NTIS | NFEC-2013-02-175505 | E-TUBE | ||

| 장비분류 | 분석장비 | 기술분야 | 소성가공 | |

| 보유센터 | 대구뿌리기술지원센터 | 장비상태 | 정상 | |

| 구축일 | 2012-12-12 | 구축비용 | 277,517,525원 | |

| 수수료 | 43000원/시간 | 바우처 사용 | 사용가능 | |

| 담당자 | 이성윤 | 연락처 | ||

| 매뉴얼 |

|

|||

주요사항

원리 및 특징

1. Purpose:

The system is in order to support higher productivity, quality improvement and new product development through educational-industrial Cooperation, Non-contact 3D Solid Form System with high-speed and high-accuracy is required in new system design and development.

2. Stand-Alone 3D Solid Form System

The system should consist of main body, laser probe, scanning software and editing software. The four parts should be provided as a total solution from single maker.

3. Max. 6 axes available

The system should available 6 axes to conform our various research purposes.

○ Fully Automatic CNC Type XYZ –axis

○ A-axis – Fully automatically A-axis CNC Rotary Stage (CNC part rotation)

○ VW-axis – Laser Head Rotation

○ Rotates measuring parts automatically and matches the data automatically

4. CNC Type with Z-Search function

The system should be CNC type that operated automatically by program, and should have the Z-Search function that automatically searches Z-axis coordinates.

5. Scan Data Output Format

○ ASCII

○ .STL

○ .SCN (Geomagic S/W Direct Interface)

○ .LDA (Imageware S/W Direct Interface)

○ .PCN (Polywork S/W Direct Interface)

6. Gantry Type, Granite base

The main body should be operated as Gantry type, the base should be made of a fine granite.

7. Low power Diode Laser

The Laser must be lasting that does not require Gas injection or replacement.

8. Automatic Safety Device

Automatic safety device is required to protect system for the risk of Laser probe collision.

The system is in order to support higher productivity, quality improvement and new product development through educational-industrial Cooperation, Non-contact 3D Solid Form System with high-speed and high-accuracy is required in new system design and development.

2. Stand-Alone 3D Solid Form System

The system should consist of main body, laser probe, scanning software and editing software. The four parts should be provided as a total solution from single maker.

3. Max. 6 axes available

The system should available 6 axes to conform our various research purposes.

○ Fully Automatic CNC Type XYZ –axis

○ A-axis – Fully automatically A-axis CNC Rotary Stage (CNC part rotation)

○ VW-axis – Laser Head Rotation

○ Rotates measuring parts automatically and matches the data automatically

4. CNC Type with Z-Search function

The system should be CNC type that operated automatically by program, and should have the Z-Search function that automatically searches Z-axis coordinates.

5. Scan Data Output Format

○ ASCII

○ .STL

○ .SCN (Geomagic S/W Direct Interface)

○ .LDA (Imageware S/W Direct Interface)

○ .PCN (Polywork S/W Direct Interface)

6. Gantry Type, Granite base

The main body should be operated as Gantry type, the base should be made of a fine granite.

7. Low power Diode Laser

The Laser must be lasting that does not require Gas injection or replacement.

8. Automatic Safety Device

Automatic safety device is required to protect system for the risk of Laser probe collision.

사용예

중소기업의 신제품개발 등의 분야에 활용함으로써 제품양산에 앞서 3D 설계 데이터를 바탕으로 디자인 검토 및 수정이 가능하여 제품개발기간의 단축 등의 기술경쟁력 향상에 기여할 수 있음.

- 대기업과 중소기업 간의 기술 격차 해소를 통한 경쟁력 향상 기여함과 동시에 기업체 교육, 훈련 참여로 신 기술력 향상 및 보급

- 대기업과 중소기업 간의 기술 격차 해소를 통한 경쟁력 향상 기여함과 동시에 기업체 교육, 훈련 참여로 신 기술력 향상 및 보급

활용분야

상기 시스템은 Line Laser 기술과 다양한 Software의 기능을 이용한 Reverse Engineering & Inspection 분야의 대표적인 Technology 임.

- 신속하게 3차원 입체 모형을 Line Laser와 최대 6축 (X,Y,Z,A,V,W축)을 이용하여 빠르게 Scanning하여 Prototyping 개발, CAD/CAM System, Mold & Die Manufacturing과 관련 하여 이용되고 있다.

- 상기 시스템을 이용함으로써 생산과정의 오류를 제거하고 개발기간 및 비용을 절감하여 개발 경쟁력을 높이고자 이용되는 첨단 기술 임.

- 신속하게 3차원 입체 모형을 Line Laser와 최대 6축 (X,Y,Z,A,V,W축)을 이용하여 빠르게 Scanning하여 Prototyping 개발, CAD/CAM System, Mold & Die Manufacturing과 관련 하여 이용되고 있다.

- 상기 시스템을 이용함으로써 생산과정의 오류를 제거하고 개발기간 및 비용을 절감하여 개발 경쟁력을 높이고자 이용되는 첨단 기술 임.