1. High performance SIMS system for surface analysis Techniques. 2. The analysis chamber should be designed for below facilities, as followings : 1) Static SIMS 2) Dynamic SIMS 3) Imaging SIMS 4) 3-D Analysis3. All the materials used in the construction of vacuum system are UHV compatible, low vapor pressure materials. 4. All the weldings are tungsten inert gas welding. 5. All the chamber and connecting walls should be chemically clean to minimize outgas. 6. The system is bakeable up to 100。C or more. 7. Electric supply : 220vac, 60Hz, three phase○ 주요사양1. Secondary Ion Mass analyzer- Mass resolution at low mass (29 u) : > 11,000 (FWHM, forAtoms & clusters)- Mass resolution at higher mass (> 200 u) : >16,000 (FWHM)- Mass range : > 8,000 u - Detector : a combined microchannel plate (MCP), scintillator photomultiplier ion detector, and a multi-stop converter (TDC) with 50 ps time - Sensitivity : under ppm concentration for all elements- Lateral resolution : < 100 nm - Depth resolution : < 0.5 nm2. UHV analysis chamber and Fast entry air lock - Pumping : vacuum buffer, scroll pump, drag pump, and turbomolecular pump - Base Pressure : < 5.0 x 10 E10 torr 3. Primary ion source - Max. beam energy : 30 KeV - Max. DC ion current in Spectrometry mode : >30 nA- Max. DC ion current in Imaging mode : 400 pA- Min. beam diameter : < 100 nm - Min. Pulse width : < 1.0 ns (FWHM)- Max. pulsed target current : >20 pA4. A motorized five-axes UHV sample stage with - X > 50 mm, Y > 100 mm, Z > 20 mm, tilt = -15° to +45°, and endless rotation. - Full automation and computer control of all axes, including continuous motors and position encoders, an ESCOSY (registered trade mark of Raith GmbH, Dortmund, Germany) motor controller, joystick, PC interfacing, and ESCOSY PLUS navigation software package allowing for unattended batch processing, Macro Raster operation by stage movement, computer controlled eucentric rotation and tilt, and sample navigation based on wafer maps, defect maps, and position lists, imported from surface scanners and optical inspection tools. 5. Two CCD high resolution video cameras - Sample observation for analysis area location - Macro and Micro version 6. A high quality Everhart-Thornley secondary electron detector - For scanning ion induced secondary electron topographical imaging. 7. A self-adjusting charge compensation system - Synchronized with ion gun pulsing to neutralize the positive charge after each ion pulse. 8. Gas flooding system- Gas flooding system for the sample under analysis, including gas bottle, manual leak valve, and nozzle allowing the exposure of sample to inert and reactive gases. Flooding the sample with Oxygen leads to a significant enhancement of the ionization probability for positive secondary ion species. 9. Data system - Hardware : A high end PC including Microsoft Windows™, a 24'' flat at scree Colour inkjet printer : 600 dpi or bette DVD writer : DVDRW, buffer 2MB, speed ; over X16- Software : SIMS software licenses for the instrument PC and one off-line PC, and one license for SIMS library with search engine.

뿌리장비 예약

장비 상세정보

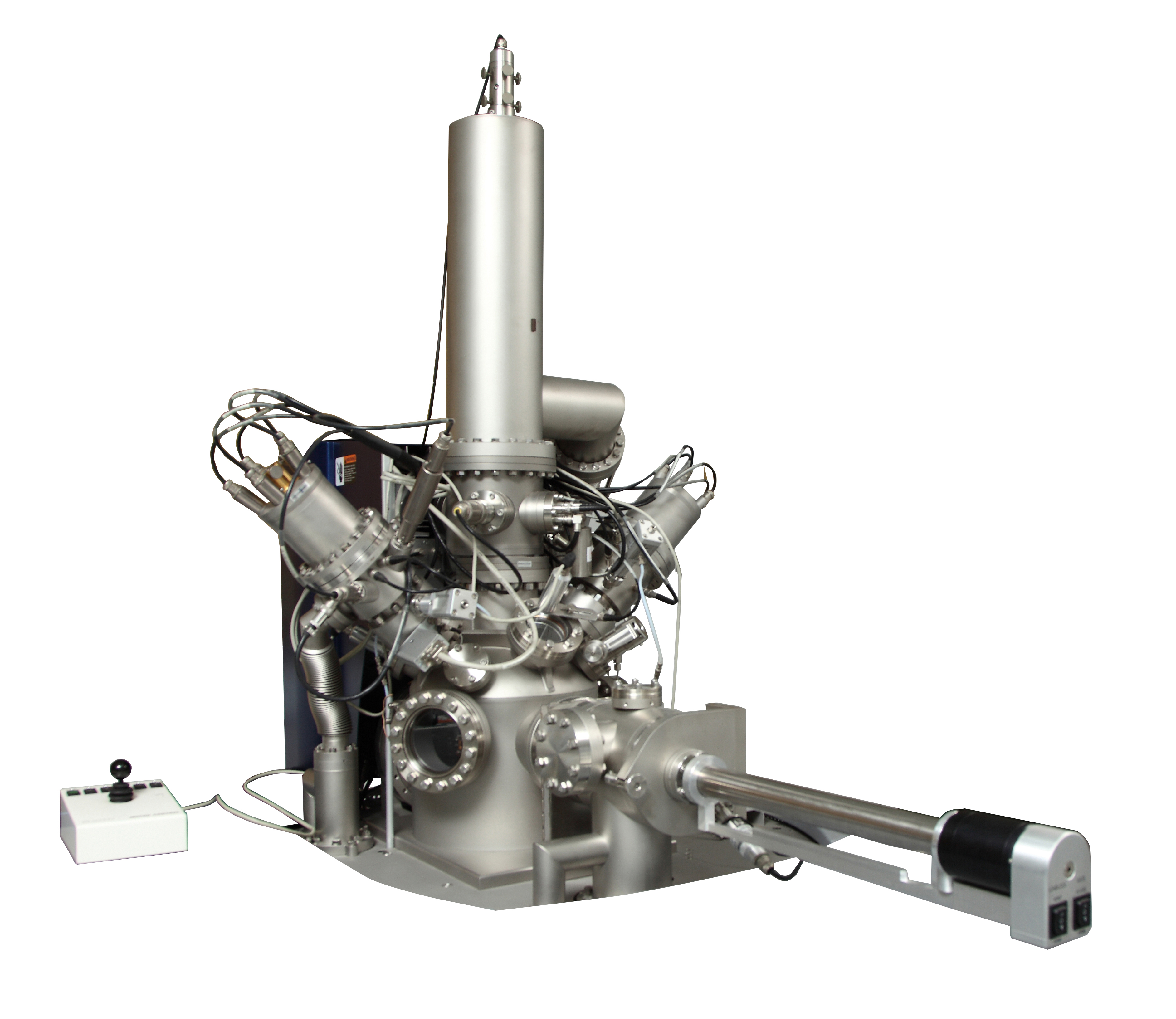

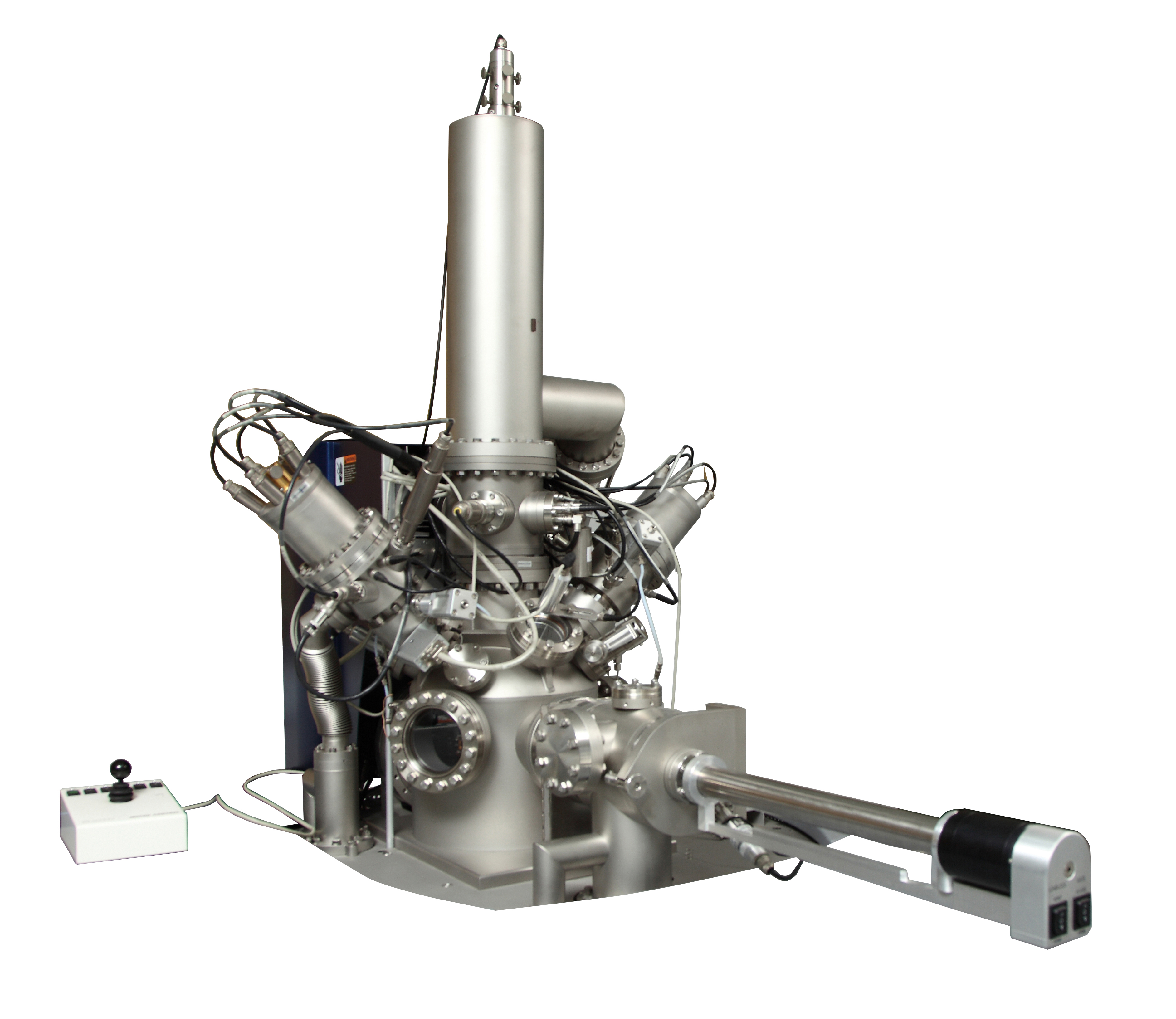

| 장비사진 | 장비명 | 이차이온질량분석기(Secondary Ion Mass Spectrometry (SIMS)) | ||

|---|---|---|---|---|

|

제작사 | Ion-tof | 모델명 | TOF-SIMS 5 |

| NTIS | NFEC-2012-06-165615 | E-TUBE | 1206-B-0096 | |

| 장비분류 | 분석장비 | 기술분야 | 표면처리 | |

| 보유센터 | 시흥뿌리기술지원센터 | 장비상태 | 정상 | |

| 구축일 | 2012-06-20 | 구축비용 | 947,189,011원 | |

| 수수료 | 표면분석-최초 시편 1개: 94,000원, 추가 시편 1개당 27,000원 추가, Depth profile-최초시편 1개:135,000원, 추가 시편 1개당 71,000원 추가 | 바우처 사용 | 사용가능 | |

| 담당자 | 구석본 | 연락처 | 032-850-0252 | |

| 매뉴얼 |

|

|||

주요사항

원리 및 특징

표면 미세 불량 및 박막 불순물에 대한 검출 장비로서, 지속적으로 미세·정밀화되는 첨단산업의 소재·부품 산업에 있어 글로벌 경쟁력을 갖춘 뿌리 기업으로 성장하기 위한 필수 분석 장비. Sample표면 원자층에 고에너지의 이온빔을 충돌시켜 방출되는 표면의 입자들과 중성원자등 2차 이온들을 이용해 표면 성분 정밀 분석

사용예

반도체 칩이나 PCB 표면의 표면 불량 원인을 규명하기 위한 미세 잔류물 검출 : 이차이온질량분석기를 이용한 Aromatic compound (C7H7) 검출을 통해 마이크로 용접재료인 OSP 의 표면 잔류물임을 확인할 수 있음

활용분야

1. Secondary Ion Mass analyzer 1 set 1.1. Mass resolution at low mass (29 u) : > 11,000 (FWHM, forAtoms & clusters) 1.2. Mass resolution at higher mass (> 200 u) : >16,000 (FWHM) 1.3. Mass range : > 8,000 u 1.4. Detector : a combined microchannel plate (MCP), scintillator photomultiplier ion detector, and a multi-stop converter (TDC) with 50 ps time 1.5. Sensitivity : under ppm concentration for all elements 1.6. Lateral resolution : < 100 nm 1.7. Depth resolution : < 0.5 nm2. UHV analysis chamber and Fast entry air lock 2.1. Pumping : vacuum buffer, scroll pump, drag pump, and turbomolecular pump 2.2. Base Pressure : < 5.0 x 10 E10 torr 3. Primary ion source 3.1. Max. beam energy : 30 KeV 3.2. Max. DC ion current in Spectrometry mode : >30 nA 3.3. Max. DC ion current in Imaging mode : 400 pA 3.4. Min. beam diameter : < 100 nm 3.5. Min. Pulse width : < 1.0 ns (FWHM) 3.6. Max. pulsed target current : >20 pA4. A motorized five-axes UHV sample stage with 4.1. X > 50 mm, Y > 100 mm, Z > 20 mm, tilt = -15° to +45°, and endless rotation. 4.2. Full automation and computer control of all axes, including continuous motors and position encoders, an ESCOSY (registered trade mark of Raith GmbH, Dortmund, Germany) motor controller, joystick, PC interfacing, and ESCOSY PLUS navigation software package allowing for unattended batch processing, Macro Raster operation by stage movement, computer controlled eucentric rotation and tilt, and sample navigation based on wafer maps, defect maps, and position lists, imported from surface scanners and optical inspection tools. 5. Two CCD high resolution video cameras 5.1. sample observation for analysis area location 5.2. Macro and Micro version 6. A high quality Everhart-Thornley secondary electron detector 6.1. for scanning ion induced secondary electron topographical imaging. 7. A self-adjusting charge compensation system 7.1. synchronized with ion gun pulsing to neutralize the positive charge after each ion pulse. 8.Gas flooding system 8.1. Gas flooding system for the sample under analysis, including gas bottle, manual leak valve, and nozzle allowing the exposure of sample to inert and reactive gases. Flooding the sample with Oxygen leads to a significant enhancement of the ionization probability for positive secondary ion species. 9. Data system 9.1. Hardware : A high end PC including Microsoft Windows™, a 24'' flat at screen Colour inkjet printer : 600 dpi or better DVD writer : DVDRW, buffer 2MB, speed ; over X16 9.2. Software : SIMS software licenses for the instrument PC and one off-line PC, and one license for SIMS library with search engine. 10. One set of spare parts and Tool kit should be provided.○ 특징표면 미세 불량 및 박막 불순물에 대한 검출 장비로서, 지속적으로 미세·정밀화되는 첨단산업의 소재·부품 산업에 있어 글로벌 경쟁력을 갖춘 뿌리 기업으로 성장하기 위한 필수 분석 장비임○ 구성 및 성능1. Secondary Ion Mass analyzer2. UHV analysis chamber and Fast entry air lock3. Primary ion source4. A motorized five-axes UHV sample stage5. Two CCD high resolution video cameras6. A high quality secondary electron detector7. A self-adjusting charge compensation system8. Gas flooding system9. Data system